Polymer overload vs sustainability design

When teaching Design and Technology is it very important to emphasise the importance of the designer and how they can support sustainability in the use of material, processes, manufacturing techniques etc. The article below can be used with your students as an introduction to the topic. The activity of making bioplastics is fun and quick and can be completed very easily in 40 minutes. I hope you enjoy it!

Justin Harris (author of Collins Cambridge IGCSE® Design and Technology)

Why should we think about sustainability?

You are sat at a screen made of a polymer, (ok, you are maybe using a product from another company that uses aluminium alloys) but you probably use a keyboard with polymer keys. You may have a pen near you made from injection moulded polymers. The charger and cables you use have polymer cases and covers – you get the point! Polymers are all around us, we rely on them in many ways in our modern lives. They provide so many uses and in many ways make our lives easier. Polymers or plastics are cheap, easy to manufacture in volume, and have a range of colours, textures and finishes to appease our aesthetic needs. We just can’t seem to get enough of them, we love them.

However, there is a flip-side to this. The petrochemicals and natural gases that they are made from will one day inevitably run out. Oil based polymers also take a very long time to degrade. That water bottle you recently drank out of and threw in the bin will be in a landfill site, in a river or ocean for over 500 years possibly. You only used if for a few minutes. Is this right?

Karim Rashid, a famous designer in the full length film about design called “Objectified”  once said “If the shelf life of a high-tech object is less than eleven months, it should be all 100% disposable. You know, I think my laptop, in a way, should be made of cardboard or my mobile phone could be a piece of cardboard or it could be just made out of something like, I don’t know, sugar cane or some bio-plastic, etc. Why on Earth does anything have to be built to be permanent? ” What do you think about this quote? Do you think he is right?

once said “If the shelf life of a high-tech object is less than eleven months, it should be all 100% disposable. You know, I think my laptop, in a way, should be made of cardboard or my mobile phone could be a piece of cardboard or it could be just made out of something like, I don’t know, sugar cane or some bio-plastic, etc. Why on Earth does anything have to be built to be permanent? ” What do you think about this quote? Do you think he is right?

The use of oil based polymers to manufacture the millions of products we use every day continues and this has a major impact on our environment. It is time to change the way we think and manufacture. We need to start thinking more sustainably.

Find out more about what happens to plastic after we’ve used it – and what might happen to it in the future. Watch the short documentary called The Plastics Age. More information on this topic can also be found in Collins Cambridge IGCSE® Design and Technology, page 73-74.

What does this sustainability mean in Design?

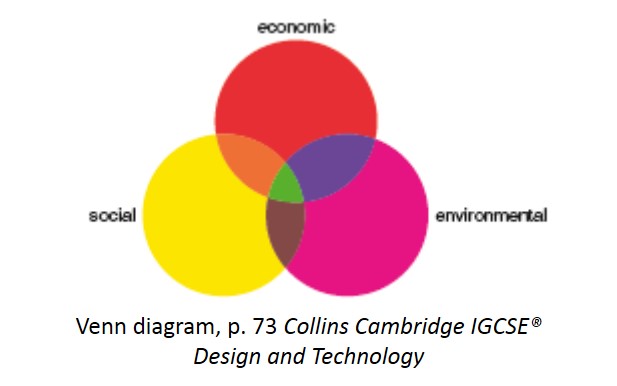

The Venn Diagram demonstrates the interaction of economy, environment and society. When all of these elements are balanced we hope to have a sustainable product/service. But what are the three elements.

The Venn Diagram demonstrates the interaction of economy, environment and society. When all of these elements are balanced we hope to have a sustainable product/service. But what are the three elements.

Society relates to the people making products or providing services. They need to be treated and paid fairly and not exploited. Materials need to be sourced for manufacture at a local level. Working areas must be safe.

Economic relates to job creation for people, profit sharing and upskilling workers.

Environment in the context of this article relates to selecting appropriate materials, using manufacturing methods that save energy and resources which do not pollute and also ensuring products can be recycled, reused etc.

Products and services that take all of the above into account can be labelled sustainable. However, it can be difficult to achieve and compromises have to be made.

In terms of making sustainable plastic products, the material is the main issue. With plastics, the material not being biodegradable is the most obvious problem. Plastics, can, however be recycled and I will talk about this later but let’s first turn to bioplastics.

What are Bioplastics and how to make them?

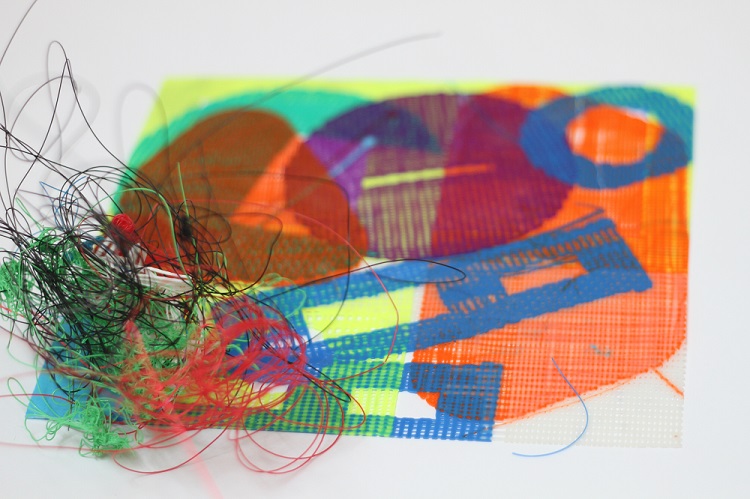

A bioplastic is a plastic derived from naturally occurring renewable materials such as vegetable fats, vegetable oils and starch from products such as rice, potato and corn, to name a few. Many of these are biodegradable however some are not! However, they are all more environmentally friendly and their development for future products and sustainability is to be encouraged.

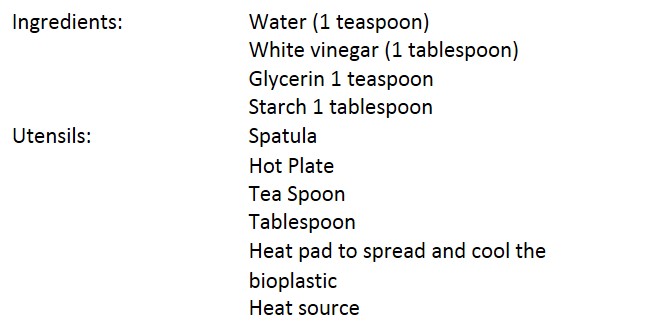

You can make your own bioplastic in school with some basic household materials. This video shows how to make your own bioplastic – and here is a list of ingredients and utensils you will need:

Bioplastic Recipe and method

If you are particularly interested in bioplastic development you may wish to research the following materials:

- Polyactic acid (PLA)

- Polyhydoxyalkanoates (PHA)

- Ply-3-hyroxbytyrate (PHB)

These are commercially available and used in many products at present.

Other useful Youtube links:

Making plastic from a banana peel https://www.youtube.com/watch?v=BMR-oMpCbjo

A more chemistry based film https://www.youtube.com/watch?v=y1joh_t1thc

Recycling thermoplastics

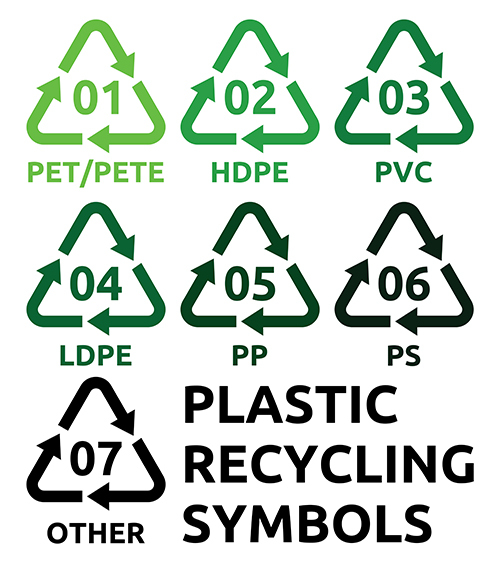

Another way of extending the life of petroleum based plastics is to recycle them. You may have noticed that many thermoplastics (they can be reheated and moulded) have a triangle and a number inside them. This system identifies the plastic so it can be grouped together and recycled.

Plastics with a number from 1-6 can be chopped up into small pieces, reheated and turned into new raw materials which can then be industrially processed again into new products.

Plastics with a number from 1-6 can be chopped up into small pieces, reheated and turned into new raw materials which can then be industrially processed again into new products.

It is hard to believe that this is not (yet?) a widespread industry considering how much recyclable plastic that is being thrown away across the world every day. The change is happening but it needs to be more widespread to have an effect.

See the images and descriptions below for a few examples of everyday polymers (in this case packaging) that has been group together to be remade into other useful products. This extends the life of the original polymer.

Image credits: All images taken from Shutterstock unless stated otherwise.